But how is paper actually made. Clothes are made by weaving together yarns such as cotton and wool spun from natural fibers.

How Paper Is Made Sappi Sappi Global

How Paper Is Made Sappi Sappi Global

After mixing them together Cai Lun then mashed the ingredients into a pulp.

How is paper made. We plant over a 150 millions trees in our plantations every year before they are transported to our mills to be turned into paper. However engineers have devised clever ways to ensure that very little water is wasted. In fact a majority of the wood chips used are actually the waste products of sawmills.

To make paper trees are cut down. Conifer trees are often used for paper as they have long fibers that make the paper stronger. Pulp is mixed with water as well as additional fillers and additives and then pumped onto a belt.

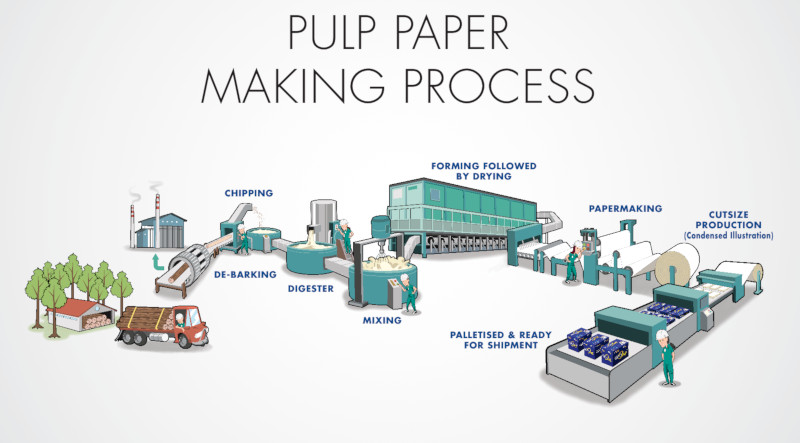

The trees are cut down and the branches are cut off and theyre loaded onto a truck where they go to the paper mill. However there are three key steps to the process of papermaking. Paper is more like the fabric we call felt made without the weaving stage by pressing together cellulose fibers extracted from plants and trees so they knit and fuse to form a strong solid but still very flexible mat.

Even the chemicals used to bleach the pulp dont include. As it aged the lignin present would also cause the paper to turn yellow. Paper also commonly comes from recycled material like old paper and cardboard.

Paper mills continued to use the Chinese method of combining old rags and cloth into a mix. Once the mill process has begun the collected paper is thrown into the pulper along with waterThe two are squashed and churned until the paper dissolves into the waterThe process is called pulping and produces what is called the vehicle which means it is the base fiber in the paper for the agro-industrial fiber to be added. While the felt used.

The paper pulp from wood chips recycled paper or both is fed into the paper-making machine. Notebook paper comes from a multi step process of cutting down trees grounding them into pulp and then manufacturing the substance into dry usable sheets of paper. How do we turn wood into sheets of paper for our use.

The fibers from a tree are called cellulose. Today paper produced is smooth soft and. How Does a Paper Making Machine Work.

Papermaking actually involves various processes to turn that wood log into our everyday paper products. Paper can be made from a. Due to technological limitations the paper made throughout history was coarse and unrefined.

Paper is made from the mix of all types of trees. A pump sprays a thin layer of the liquid paper pulp onto a moving wire. Some papermakers use a mechanical pulping process instead where the wood chips are literally beaten to a pulp From pulp to paper.

कगज कस बनय जत ह How is paper made Shorts Techno Gamerz. Paper for recycling is mixed with processed water and then stirred in a giant stainless steel vat called a pulper to make a fibre suspension. Impurities are removed using a series of screens to ensure that we only produce high-quality paper that can be used to make high-performance packaging.

At least 100L of water is required to make 1kg of paper. Experts believe that his original concoction contained bark hemp and rags in water. Papyrus is made by lamination of natural plants while paper is manufactured from fibres whose properties have been changed by maceration or disintegration.

However paper makers eventually began using wood as it was cheaper and more plentiful. The cellulose fibers are cleaned and screened many times to get them ready to be made into paper. In the Wet Press Section the pulp moves off of the mesh belt onto a felt belt.

Cai Lun a Chinese Imperial Court official invented paper in 105 AD in Leiyang China. Almost 90 of the water is recycled by soaking or recirculating it on a mesh of pipes throughout the long process.