There is a lot of support for passive carbon capture methods such as enabling soil sequestration and reducing intensive soil management such as. As of today five more carbon capture and storage facilities are being constructed and another 20 are in various stages of development globally.

Recent Advances In Carbon Capture Storage And Utilisation Technologies A Review Springerlink

Recent Advances In Carbon Capture Storage And Utilisation Technologies A Review Springerlink

Costain ETI funded project.

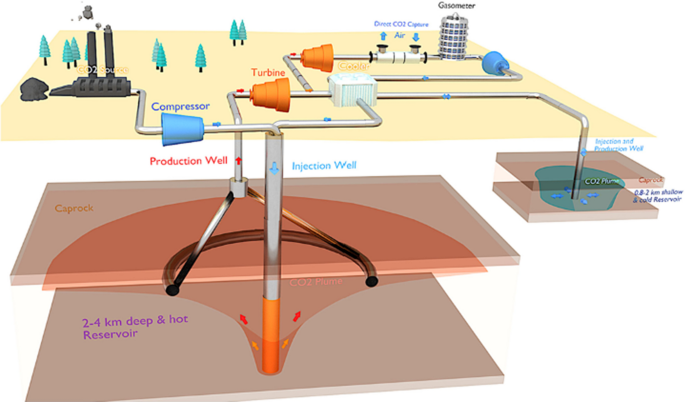

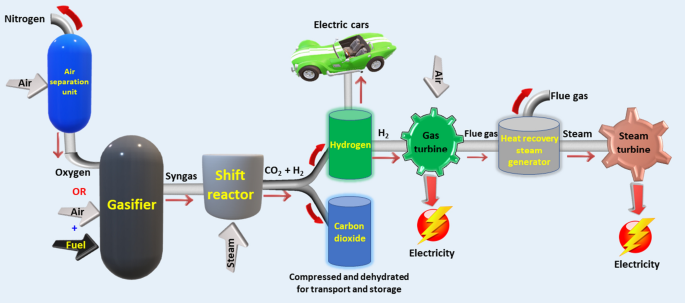

Current carbon capture technology. The captured CO 2 gas is then compressed so it becomes liquid-like and. With a rough approximation of electricity revenues we estimate utilisation costs of between 60 and 160 per tonne of CO2. Currently there are three capture technologies of trapping CO 2 from the flue gas and they are pre-combustion post-combustion and oxy-fuel combustion.

Bioenergy with carbon capture and storage. What is carbon capture usage and storage CCUS. For CCS to succeed at reducing CO2emissions from a significant fraction of large sources in the United States CO2 capture technology would need to deployed widely.

Carbon capture and storage is also used to sequester CO 2 filtered out of natural gas from certain natural gas fields. NETL is currently testing four US. With proven carbon capture technologies carbon may be sequestered into long-term crops soils and unmanaged habitats.

8 future technologies for carbon capture 1. Current technology for stripping CO2 from industrial gas streams or directly from the atmosphere remains costly and energy-intensive and existing. Complex problems require complex solutions says Angeles-Boza.

Carbon capture technology may one day be a tool to remediate high levels of CO 2 in the atmosphere but it wont ever be a cure-all for the problem of climate change. Carbon capture technology has been around for decades and is used to strip carbon out of factory emissions as well as remove carbon thats already in the air. Around 98 percent of the injected CO2.

The CO2 is then stored in the layers of rock that previously retained oil. In bioenergy with carbon capture the operator captures CO2 by growing trees produces electricity through bioenergy and sequesters the resulting emissions. Carbon capture processes there.

Carbon capture methods are diverse. There is no one perfect solution our approach must be a multicomponent one. Carbon capture offers a solution that has the potential to reduce carbon concentrations in the surrounding environment.

Carbon capture and storage CCS is a technology that can capture carbon dioxide CO 2 emissions produced from fossil fuels in electricity industrial processes which prevents CO2 from entering the atmosphere. Optimisation and Integration of Membrane Processes in Coal Fired Power Plants with CCS SP membrane Project funded by the Carnegie Trust for the Universities of Scotland. Cornell University materials scientists have invented low-toxicity highly effective carbon-trapping.

Most current carbon capture projects use a liquid to chemically remove the CO 2 before it goes out the smokestack but several new types of capture processes are under development. In recent years a class of highly absorbent nanoporous materials called metal-organic. Unlike the other two components of CCS transportation and geologic storage the first component of CCSCO2captureis almost entirely technology-dependent.

According to the World Resources Institute WRI DAC costs can vary from 250 to 600 per ton of CO2 captured. In the above-mentioned carbon capture and storage facilities the companies mainly use enhanced oil recovery where CO2 is directly injected into oil reserves to make it easier to extract oil. A big advance in carbon capture technology could provide an efficient and inexpensive way for natural gas power plants to remove carbon dioxide from their flue emissions a necessary step.

This scientific opinion responds to a request from the European Commission formulated by Commissioner Cañete Commissioner for Climate Action and Energy and addresses the climate mitigation potential of the suite of technologies that capture CO2 from industrial processes or from the air and which convert it into fuels chemicals and materials also known as carbon capture and utilisation or CCU. Next generation carbon capture technology NGCCT ScottishPower. Among these the post-combustion is widely popular as it can be retrofitted for a short to medium term without encountering any significant technology risks or changes.

Another one that is about to be tested was invented by SRI International formerly the Stanford Research Institute in. Carbon capture company Carbon Clean aims to capture CO2 for 30 or less per ton stating it is 30 more commercially viable than competitors. Some 05 to 5GtCO2 per year could be utilised and.

This refers to a chain of different technologies that can keep the carbon dioxide produced by. They range from aqueous aminesthe water-rich solvents that run through todays commercially available capture units which Jiang used as an industrial.